A Neural Network to Detect Thin hBN Layers on Wafers

Introduction

During my undergraduate research at the University of California, Berkeley (Sep 2023 - Jan 2024), I worked on Charge Transfer Dynamics in RuCl₃/hBN/WSe₂ Heterostructures under Professor Feng Wang. To enhance experimental efficiency, I independently developed a Convolutional Neural Network (CNN) that detects thin hBN layers on wafers with 95% accuracy.

Project Motivation

The current flake finding system used in laboratories cannot effectively handle thin hBN because thin hBN, wafers, and residue on tape often have similar colors. Traditional color-based algorithms frequently misidentify residue as flakes, causing significant inefficiencies as researchers need to spend considerable time distinguishing between residue and actual flakes. This inefficiency has prompted the integration of machine learning techniques for improved accuracy and efficiency.

Neural Network Architecture

The developed CNN architecture is both simple and effective. Below is the structure implemented:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

import torch

import torch.nn as nn

import torch.nn.functional as F

class Net(nn.Module):

def __init__(self):

super().__init__()

self.conv1 = nn.Conv2d(3, 6, 5) # Output: 6 channels, 59x59 feature maps

self.pool = nn.MaxPool2d(2, 2)

self.conv2 = nn.Conv2d(6, 16, 5) # Output: 16 channels, 13x13 feature maps

self.fc1 = nn.Linear(16 * 13 * 13 , 64)

self.fc2 = nn.Linear(64, 32)

self.fc3 = nn.Linear(32, 2) # Output: 2 classes (Sample, Tape)

def forward(self, x):

x = self.pool(F.relu(self.conv1(x)))

x = self.pool(F.relu(self.conv2(x)))

x = torch.flatten(x, 1) # Flatten all dimensions except batch

x = F.relu(self.fc1(x))

x = F.relu(self.fc2(x))

x = self.fc3(x)

return x

net = Net()

net.to(device)

Dataset and Preprocessing

The dataset comprised approximately 50,000 images, manually labeled as tape or flake, with flake images constituting about 2% of the dataset.

Preprocessing Steps:

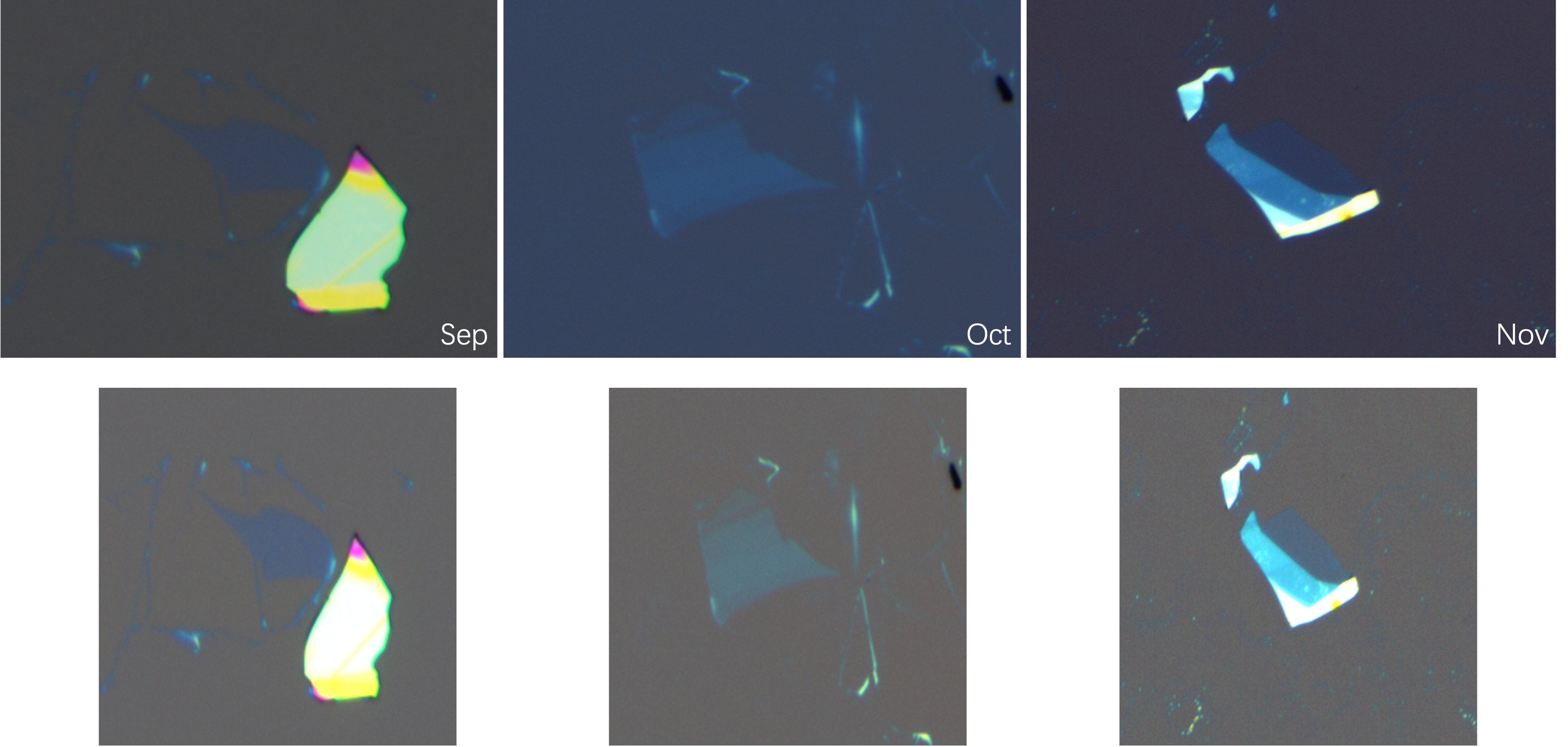

Color Normalization: Adjusting the images based on wafer color standards to account for color variation in wafers scanned at different times. The standardization result is shown below.

Color variation in wafers scanned at different months and the standardized result after applying color normalization

Color variation in wafers scanned at different months and the standardized result after applying color normalization- Standard Transformations:

- Scaling

- Type Conversion

- Normalization

- Data Augmentation for Flake Images:

- Rotation

- Symmetry Transformations

- Scaling

These methods helped enhance the dataset, particularly augmenting the minority flake class for better model training.

Training and Testing

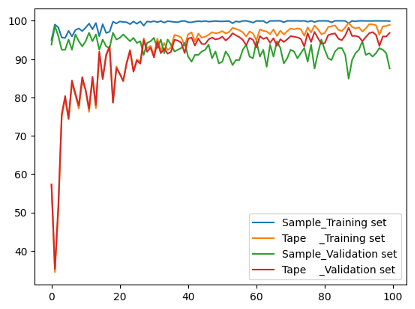

The training process involved splitting the dataset, with 10% reserved as a validation set. Following are the results after 400 epochs of training:

1

[Epoch 396/400] [Loss: 19.741972] [Acc: T_S: 99.32% T_T: 95.51% V_S: 94.95% V_T: 94.71%] [Time: 109.3]

Accuracy Metrics:

- T_S (Sample): Training set accuracy for Sample (flake)

- T_T (Tape): Training set accuracy for Tape

- V_S (Sample): Validation set accuracy for Sample (flake)

- V_T (Tape): Validation set accuracy for Tape

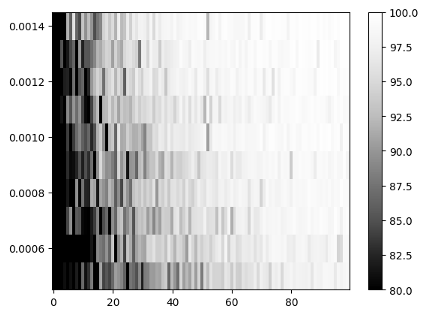

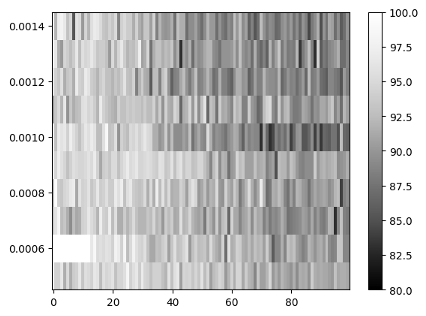

The following sections highlight the model performance at different learning rates and epoch counts:

Accuracy of Sample identification (flake) at different learning rates and epochs.

Accuracy of Sample identification (flake) at different learning rates and epochs.  Accuracy of Tape identification at different learning rates and epochs

Accuracy of Tape identification at different learning rates and epochs  Accuracy at learning rate 0.0007 over epochs.

Accuracy at learning rate 0.0007 over epochs.

Results and Visualizations

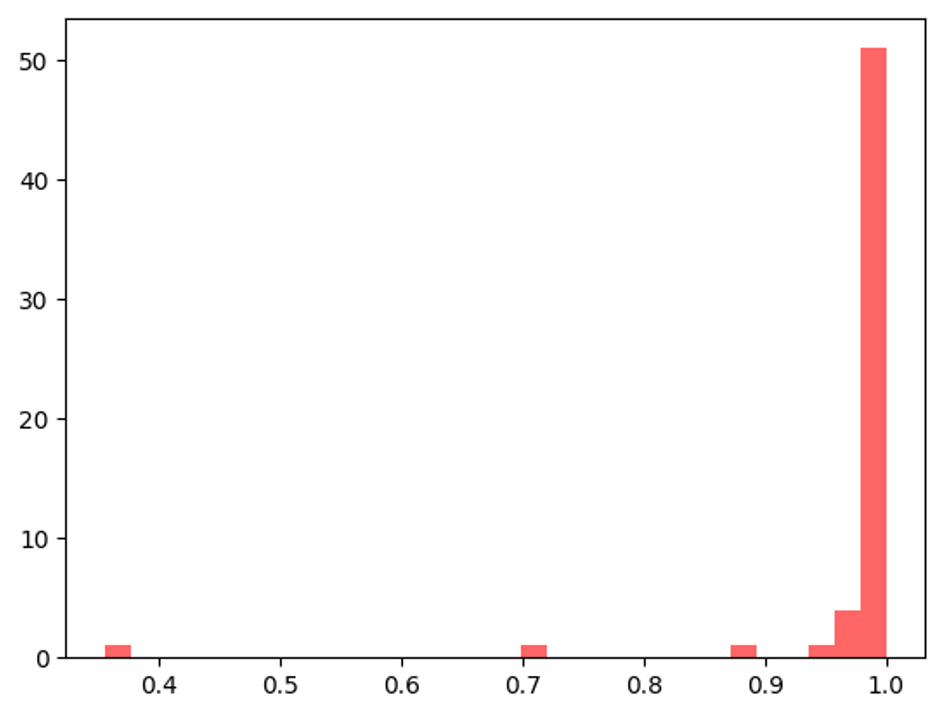

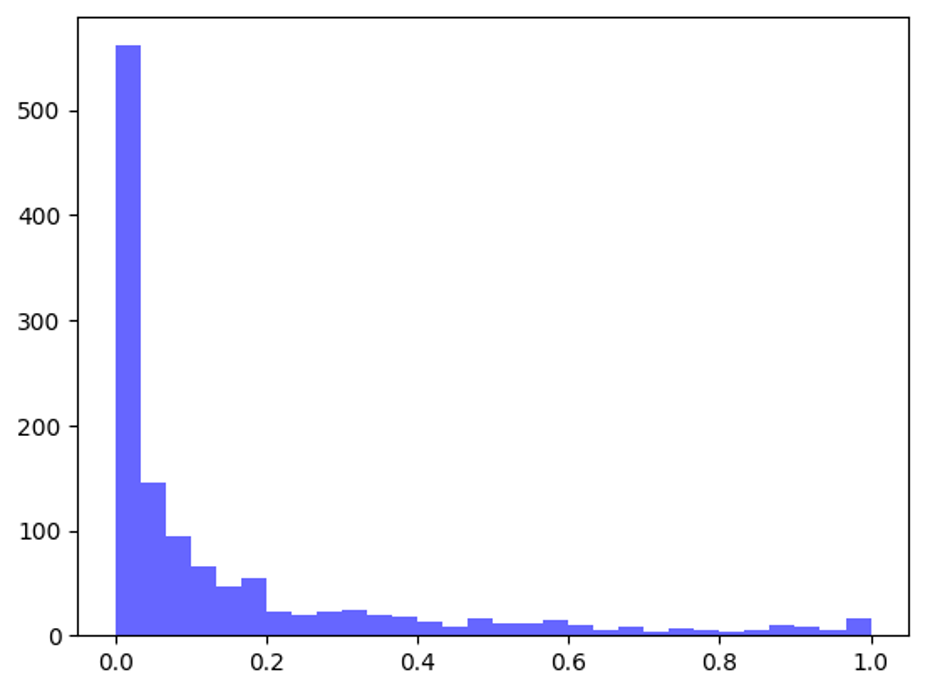

The validation set’s weight distributions and samples correctly/incorrectly identified by the model are illustrated below:

Weight Distribution of Sample (flake)

Weight Distribution of Sample (flake)  Weight Distribution of Tape

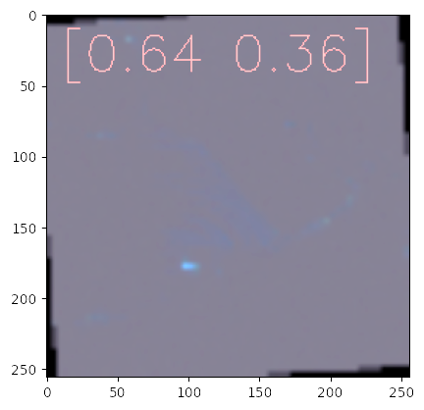

Weight Distribution of Tape  Incorrectly Identified Samples (flake)

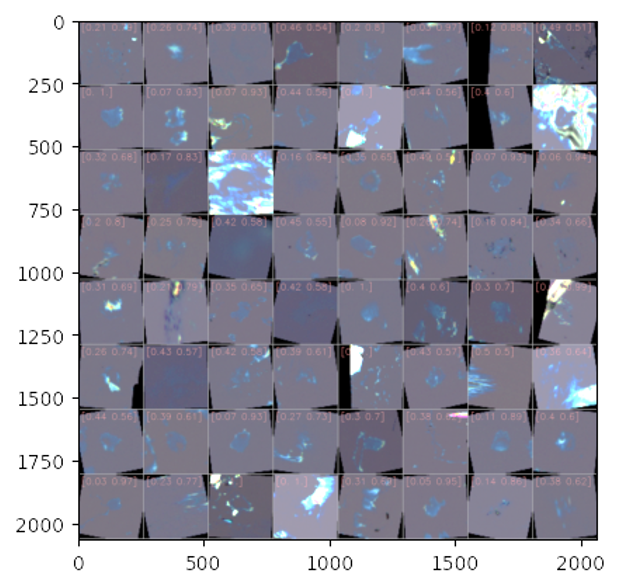

Incorrectly Identified Samples (flake)  Incorrectly Identified Tape

Incorrectly Identified Tape